Here’s a few images showing a Schneider Telemecanique Ositrack RFID system which we recently supplied and installed for a customer. The system uses the Modbus TCP/IP communication protocol to communicate with a Proface AGP375 HMI. The Proface HMI allows you to specify multiple drivers within the HMI software which allowed us to use the same Ethernet port as both a standard Ethernet UDP for communicating with the Mitsubishi Q Series PLC (QJ71E71-100 Ethernet Card) as well as communicating with the Telemecanique RFID Tag system via Modbus TCP.

The tag system was used to track parts around an automated Robot Spray Paint Line and hold information such as part type and part colour which was passed onto the ABB IRB 5400 and ABB IRB 580 Robots via direct I/O handshaking (1 x ABB IRB 580 Robot) and CC-Link (3 x ABB IRB 5400 Robots) communications from the PLC.

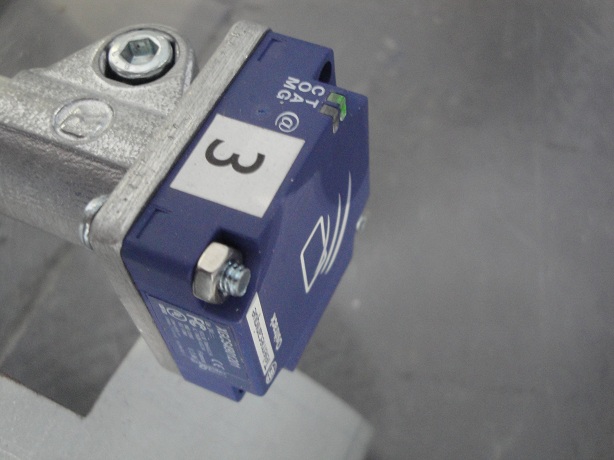

The RFID Tag System that we supplied included 3 main elements as well as the connecting cables and ‘T’ adaptors as required:

1. Telemecanique Ositrack Ethernet Box XGSZ33ETH

2. Telemecanique Ositrack Compact Control Station XGCS4901201

3. Telemecanique Ositrack Electronic Tag XGHB320345

I’ve just realised that some of you may not be familiar with the good old British fifty pence piece so here’s a picture showing the tag alongside a few more coins that you will hopefully recognise and get a better idea of the tag size. The tag has a 30mm diameter and has a nominal sensing distance of either 48mm or 65mm depending on the control station used.

Please let us know if you’re looking for any help installing an RFID system or require some friendly advice on part tracking solutions using RFID, PLCs etc.